Web Menu

Product Search

Exit Menu

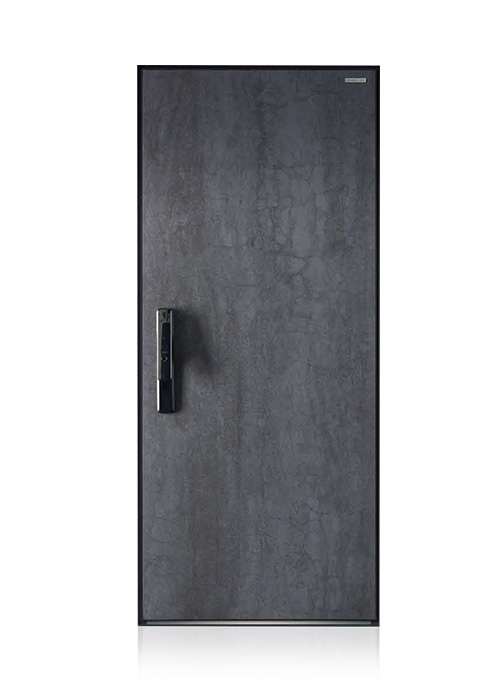

Cast Aluminum Doors: Strength and Elegance Redefined for Modern Entrances

Cast Aluminum Doors have gained significant popularity, especially in the residential and commercial building sectors. With their blend of durability, aesthetics, and practicality, these doors are becoming a preferred choice over traditional Steel Doors. Cast aluminum doors not only offer robustness and security but also bring a stylish, modern look that enhances any entrance.

Material Characteristics: Why Choose Cast Aluminum Over Steel Doors?

The material properties of cast aluminum make it an excellent alternative to steel doors. Here are some key benefits:

Strength and Durability

Cast aluminum doors provide exceptional strength while being lightweight. Unlike steel doors, which can rust over time, cast aluminum is corrosion-resistant, making it ideal for various environmental conditions, including coastal areas.

Corrosion Resistance

Cast aluminum naturally resists corrosion, which is particularly advantageous for doors exposed to outdoor elements. In contrast, steel doors are prone to rust if not properly treated or coated, especially in humid environments.

Aesthetic Flexibility

Cast aluminum offers the flexibility to create intricate designs that are difficult to achieve with steel. This material can be molded into complex patterns, giving homeowners and businesses the option to personalize their entrances with unique, elegant styles.

Design Innovations in Cast Aluminum Doors

One of the standout features of cast aluminum doors is the design potential. Unlike traditional steel doors, which often have limited customization options, cast aluminum allows for:

Intricate Patterns

Casting techniques allow aluminum doors to feature intricate patterns, such as floral motifs, geometric designs, or custom insignias. These details add a touch of elegance to any property.

Customizable Colors and Finishes

Cast aluminum doors can be painted or powder-coated in a variety of colors. This flexibility means homeowners can match their doors to their home's exterior design, something that steel doors often lack due to limitations in color options.

Mixed Material Design

Many manufacturers are combining cast aluminum with glass inserts, providing options for partial transparency without compromising security. These doors can serve both aesthetic and practical purposes, enhancing entrances while providing light and visibility.

Manufacturing Process of Cast Aluminum Doors

The manufacturing of cast aluminum doors involves a detailed process to ensure precision and quality:

Mold Creation

The first step involves creating a mold based on the door's design. This mold shapes the molten aluminum, allowing for complex, detailed patterns.

Casting and Cooling

Molten aluminum is poured into the mold, where it cools and hardens into the desired shape. This casting process allows for unique, intricate designs that are not achievable with steel doors.

Finishing and Quality Control

Once the casting process is complete, the door undergoes finishing, including polishing, coating, and painting. Quality control checks ensure that each door meets safety and durability standards, providing customers with a long-lasting, high-quality product.

Environmental Considerations of Cast Aluminum Doors

In an era where sustainability is crucial, cast aluminum doors offer notable environmental benefits:

Recyclability

Aluminum is highly recyclable without losing its quality. This property enables manufacturers to use recycled aluminum in production, reducing the need for virgin material and lowering the environmental impact.

Lower Carbon Footprint Compared to Steel

Aluminum production requires less energy than steel production, resulting in a smaller carbon footprint. Opting for cast aluminum doors over steel doors can contribute to a building's overall sustainability, which is increasingly valued in modern architecture.

Long Lifespan

Due to its durability and corrosion resistance, cast aluminum requires less frequent replacement or repair, further reducing the environmental impact over its lifespan.

Market Trends: Growing Demand for Cast Aluminum Doors

The demand for cast aluminum doors is increasing, driven by factors such as durability, aesthetics, and sustainability. Key market trends include:

Growth in Residential and Commercial Sectors

With rising awareness about the benefits of cast aluminum, both homeowners and businesses are investing in these doors for enhanced security and style.

Technological Innovations

Advancements in casting technology have improved the quality and design possibilities for cast aluminum doors. Innovations such as 3D modeling and high-precision casting ensure that doors are both aesthetically pleasing and highly functional.

Sustainability Trends

The shift toward sustainable materials has fueled interest in cast aluminum doors. As eco-conscious consumers seek materials with a lower environmental impact, cast aluminum has become an appealing alternative to traditional steel.

Applications and Case Studies: Where Cast Aluminum Doors Shine

Cast aluminum doors are versatile, making them suitable for various applications. Examples of usage include:

Residential Entrances

Homeowners appreciate cast aluminum doors for their durability and customizable design. Whether for a modern or traditional look, cast aluminum doors add sophistication and value to any home.

Commercial Buildings

In retail stores, offices, and hospitality sectors, cast aluminum doors are chosen for their security features and aesthetic appeal. Businesses benefit from the doors' ability to withstand high traffic and resist wear.

Case Study: Renovation Project

In a recent commercial building renovation, cast aluminum doors were installed to enhance the building's entrance. The doors featured custom patterns and a corrosion-resistant coating, which provided both a visual upgrade and long-lasting durability in a busy urban environment.

Contact Us

For any questions and feedback from customers,

we will reply patiently and meticulously.

- Tel:+86-15067968978

- Fax:+86-579-88046086

English

English  عربى

عربى